FAQ

Q: How to get the best price quickly?

A: We need to know the boiler capacity, the fuel you plan to use and the steam pressure you need, and then we can confirm the boiler model. Customer needs to provide us your name, email address and company name, and then we will send you price list immediately.

Q: What about the installation and commissioning?

A:After you receive the boiler, we will have experts to arrive at the site for boiler installation and commissioning. After boiler commissioning, we will also provide free training for boiler operators of your company.

Q: What fittings do you have for boiler installation?

A: The customer needs to leave the company name, email address and name, and we will immediately send you the detailed list of installation accessories for the boiler model you need.

Q: What installation materials do we need to prepare?

A: We will provide detailed installation material list to your email according to different boiler models.

Product parameter

YY(Q)W-700Y(Q)

The important parameters

YY(Q)W-1400Y(Q)

The important parameters

Etc

Applications

Contact us

Q: How to get the best price quickly?

A: We need to know the boiler capacity, the fuel you plan to use and the steam pressure you need, and then we can confirm the boiler model. Customer needs to provide us your name, email address and company name, and then we will send you price list immediately.

Q: What about the installation and commissioning?

A:After you receive the boiler, we will have experts to arrive at the site for boiler installation and commissioning. After boiler commissioning, we will also provide free training for boiler operators of your company.

Q: What fittings do you have for boiler installation?

A: The customer needs to leave the company name, email address and name, and we will immediately send you the detailed list of installation accessories for the boiler model you need.

Q: What installation materials do we need to prepare?

A: We will provide detailed installation material list to your email according to different boiler models.

Product parameter

| Boiler type | Heat power | Heat efficient | Pressure | Fuel | Diemension(m*m*m) |

| YY(Q)W-1200Y(Q) | 1.25MW | >90% | 1.0Mpa | Gas/Oil | 6*2.2*4 |

| YY(Q)W-1400Y(Q) | 1.4MW | >90% | 1.0Mpa | Gas/Oil | 6*2.6*4.5 |

| YY(Q)W-1750Y(Q) | 1.78MW | >90% | 1.0Mpa | Gas/Oil | 6*2.6*4.8 |

| YY(Q)W-2900Y(Q) | 3.0MW | >90% | 1.0Mpa | Gas/Oil | 6.2*3*6 |

| YY(Q)W-3500Y(Q) | 3.5MW | >90% | 1.0Mpa | Gas/Oil | 6.2*3*6 |

| YY(Q)W-4200Y(Q) | 4.2MW | >90% | 1.0Mpa | Gas/Oil | 6.3*3.1*6.1 |

The important parameters

| NO; | Name | Unit | Number | Description |

| 1 | Rated thermal power | KW | 700 | |

| 2 | Rated working power | Mpa | 1.0 | |

| 3 | Rated inlet/outlet ºC | ºC | 310/290 | |

| 4 | Design efficiency | % | 92.45(Oil) 92.13(Gas) | |

| 5 | Boiler heat efficiency | % | More than 98% | Be added economizer |

| 6 | Design fuels | / | Light oil,Gas | |

| 7 | Fuels LHV | MJ/kg | 42.917(Oil) | |

| MJ/Nm3 | 35.438(Gas) | |||

| 8 | Consumption of fuels | kg/h | 70.77(Oil) | |

| Nm³/h | 86.53(Gas) | Be added economizer | ||

| 9 | Radiation heating area | m² | 7.199 | |

| Convection heating area | m² | 28.71 | ||

| GGH heating area | m² | 10.965 | ||

| 10 | Fume temperature | ºC | 136.68(Oil) | |

| ºC | 137.02 (Gas) | |||

| 11 | Fume temperature | ºC | 60-80 | Be added economizer |

| 12 | Excess air coefficient | / | 1.15 | |

| 13 | Volume | m3 | 0.46 | |

| 14 | Bulk weight | kg | 4250 | |

| 15 | Bulk size | mm | 3256×1727×2181 | |

| 16 | Chimney | mm | Φ325×10000 | |

| 17 | Combustion model | / | Micro positive pressure | Chamber combustion |

| 18 | Boiler structure feature | Horizontal-type chamber combustion | ||

| 19 | Control way | Full automation/Manual | ||

| 20 | Ignition way | High-tension/Electrode | ||

The important parameters

| NO; | Name | Unit | Number | Description |

| 1 | Rated thermal power | KW | 1400 | |

| 2 | Rated working power | Mpa | 1.0 | |

| 3 | Rated inlet/outlet ºC | ºC | 310/290 | |

| 4 | Design efficiency | % | 92.33(Oil) 92.03(Gas) | |

| 5 | Boiler heat efficiency | % | More than 98% | Be added economizer |

| 6 | Design fuels | / | Light oil,Gas | |

| 7 | Fuels LHV | MJ/kg | 42.917(Oil) | |

| MJ/Nm3 | 35.438(Gas) | |||

| 8 | Consumption of fuels | kg/h | 138.93(Oil) | |

| Nm³/h | 169.53(Gas) | Be added economizer | ||

| 9 | Radiation heating area | m² | 13.124 | |

| Convection heating area | m² | 71.233 | ||

| GGH heating area | m² | 29.845 | ||

| 10 | Fume temperature | ºC | 139.26(Oil) | |

| ºC | 139.27 (Gas) | |||

| 11 | Fume temperature | ºC | 60-80 | Be added economizer |

| 12 | Excess air coefficient | / | 1.15 | |

| 13 | Volume | m3 | 1.08 | |

| 14 | Bulk weight | kg | 8389 | |

| 15 | Bulk size | mm | 4869×2070×2698 | |

| 16 | Chimney | mm | Φ400×10000 | |

| 17 | Combustion model | / | Micro positive pressure | Chamber combustion |

| 18 | Boiler structure feature | Horizontal-type chamber combustion | ||

| 19 | Control way | Full automation/Manual | ||

| 20 | Ignition way | High-tension/Electrode | ||

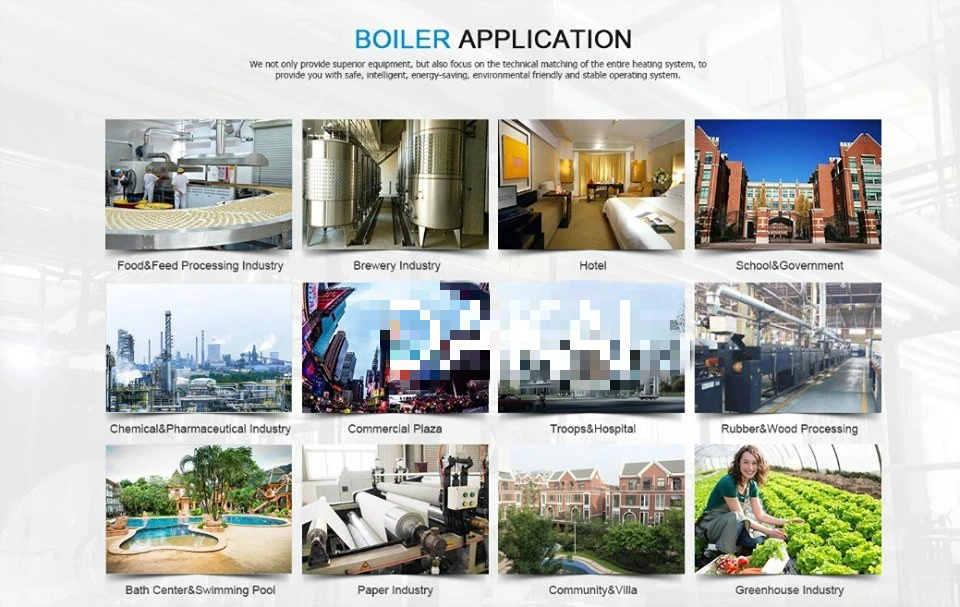

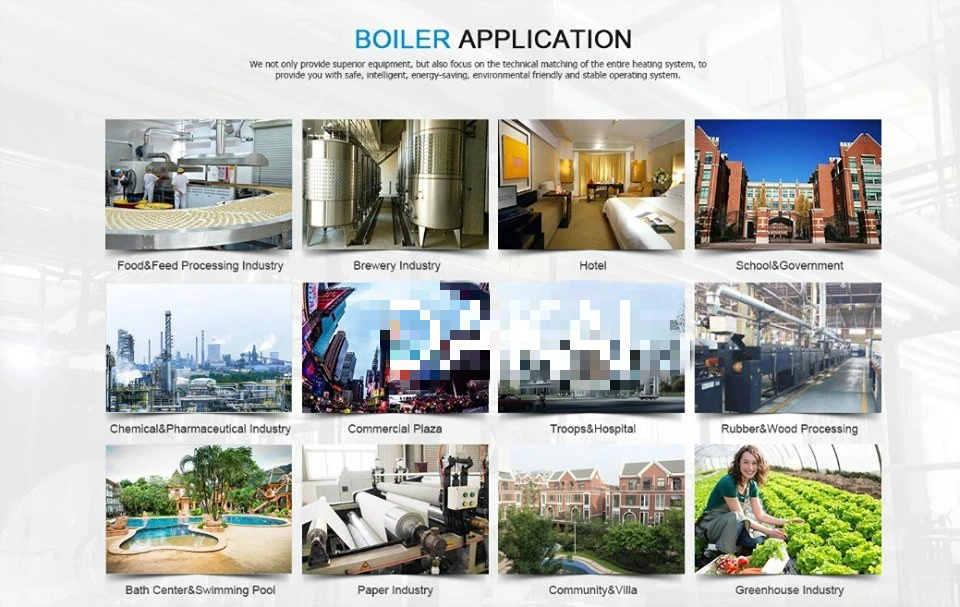

Applications

Contact us